adband

-

[PR]

×

[PR]上記の広告は3ヶ月以上新規記事投稿のないブログに表示されています。新しい記事を書く事で広告が消えます。

-

Custom heat sink manufacturers

There are a lot of electrical and electronic devices that need heat sink in life, the heat sink shell required by specific products in all walks of life is different in size, material, specification and shape, etc. So the choose and buy the cooling were often are looking for heat sink manufacturer, put forward concrete production requirements to customized processing.

- Business scope

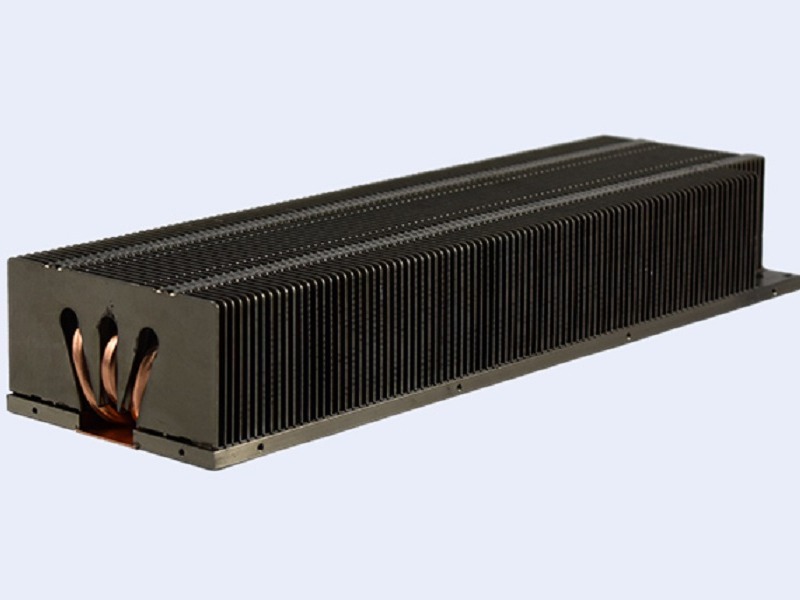

Lori has 15 years history, the main production and processing all kinds of aluminum automotive amplifier heat sink, aluminum heat sinks and aluminum LED lamp heat sink, heat pipe heat sink, skived heat sink, bonded fin heat sink, liquid cold plate and engaged in processing all kinds of aluminum products, hardware and electronic accessories, heat sink special terminal products, such as the production of the products are widely used in automotive, lighting, electronics, construction and other industries.

- The strength of the company

Since the establishment of this heat sink manufacturer, continue to explore innovation, accumulate experience, improve the system, has formed a professional system of heat sink production and processing mode.The factory covers an area of 5000 square meters, and it can provide high-end and precise materials for heat sink production. Its strong plasticity ensures that it can be customized into various sizes and shapes. Its high purity ensures that the finished products are wear-resistant, corrosion-resistant and have strong heat dissipation performance.Second, the heat sink manufacturer also bring your own mold factory, heat sink surface processing base, oxide factory, CNC machining center, strong ability of mold design and manufacturing to ensure to meet customer demand for all kinds of custom heat sink, system of perfect surface treatment technology to ensure the production of heat sink on the mechanical properties and thermal performance can be up to standard.Surface processing range includes drawing, polishing, anodic oxidation, electroplating, baking paint, radium carving, from raw material processing to surface treatment one-stop service, not only can help customers from the source to ensure the quality of the heat sink, but also to ensure the delivery time is not delayed.

PR

PR -

LED light cooling’s principle

LED lights, like all electrical products, generate heat during use, leading to an increase in the ambient temperature and its own temperature. Led strips save energy significantly. Super bright and high power led light source is adopted, together with high-efficiency power source, saving more than 80% of electricity compared with traditional incandescent lamp, and the brightness is 10 times of that of incandescent lamp under the same power.Super long life of more than 50,000 hours, is more than 50 times the traditional tungsten lamp. LED adopts the advanced packaging technology of high reliability — eutectic welding, which fully guarantees the super long life of LED. Luminous efficiency can be as high as 80lm/w, a variety of LED lamp color temperature optional, high color index, good color performance. Led light string led technology is changing with each passing day in progress, its luminous efficiency is making amazing breakthroughs, the price is also constantly reduced.

An era of white leds in the home is fast approaching.Impact resistance, strong lightning resistance, no ultraviolet (UV) and infrared (IR) radiation.No filament and glass shell, no breakage of traditional tubes, no harm to human body, no radiation. Solar light emitting diodes are solid — state semiconductor devices that convert electrical energy into visible light. The heart of the LED is a semiconductor chip, which is attached to a support with a negative electrode at one end and a positive electrode at the other end, making the whole chip encapsulated in epoxy resin. If the led oolingproblem is ignored, it will not only affect the service life of the LED lamp, but also burn the LED lamp. At the same time, it also affected the normal growth of irradiated plants.Therefore, in the manufacturing process of LED lamp, heat dissipation is a very important link.

LED lights mainly adopt the following heat dissipation measures:

Air cooling: the principle of using the fan to output the heat generated by LED light into the air is very simple. Like the cooling principle of everyday computers and televisions, convection occurs through a fan to ensure that the air around the heating elements is not too hot.Simply put, it is to use a fan to send hot air generated by LED lights to the air, and then use room temperature air to supplement, so as to achieve the effect of heat dissipation.

Natural cooling: natural cooling means working directly in the LED light without external measures. Its main principle is to make the whole LED light tube and air have a larger contact area, and the use of thermal conductivity better components. In order to better transfer the heat generated by lamps to the air, and then through natural convection, that is, the hot wind rises and the cold air compensates, thus achieving the purpose of heat dissipation of LED lamps.

Heat sink mainly use heat sink, lamp shell, system circuit board, etc., its cost is relatively low, heat dissipation effect is also good, widely used in a variety of electrical equipment.

-

Aluminum extruded heat sinks process

Aluminum extruded heat sink is a kind of common heat sink in the life, But do you know how to make aluminum extruded heat sink? Make brief introduction to everybody by Lori which is heat sink manufacturer as below.

1. The first aluminum bar must be 150-200mm short aluminum bar or pure aluminum bar for the test of aluminum extrusion die with high density fin

2. Before the die test, the center of the aluminum extrusion machine must be adjusted. The extrusion shaft, the spindle and the outlet of the die base should be in one center line.

3. During mold testing and normal production, the heating temperature of aluminum rod should be between 480-520℃.

4. Aluminum mold heating temperature according to the conventional mold temperature, controlled at about 480℃, diameter of 200mm below the flat mold insulation time should not be less than 2 hours, if the split mold insulation more than 3 hours; The mould with diameter larger than 200mm shall be insulated for 4-6 hours to ensure the uniformity of the temperature of the mould core and the external temperature.

5. Before mold test or production, clean the inner tank of the spindle cylinder with clean cylinder pad and check whether the extrusion machine runs normally when empty.

6. During the trial or initial production, the extrusion machine will turn off automatically and switch to zero.From the minimum pressure to start slowly pressure, discharge about 3-5 minutes, aluminum filling process mainly control the pressure.The pressure should be controlled within 100Kg/cm2, and the ammeter data should be within 2-3a. Generally, 80-120kg /cm2 can be discharged, and then the extrusion speed can be gradually accelerated. In normal production, the pressure should be less than 120Kg/cm2.

7. Aluminum heat sink extrusion mold in the test or production process, such as the discovery of blocking mold, teeth, speed deviation is too big phenomenon to stop immediately, and in the way of point back to unload the mold, to avoid the mold scrap.

8. In the test mold or aluminum production process, the outlet must be unobstructed, support or jig loosening according to the discharge situation reasonable grasp.Observe and find any abnormal situation at any time and deal with it in time. Stop the machine immediately when the machine stops.

9. In the process of straightening, it is necessary to carefully test the changes before and after, operate in a standard manner, apply force moderately, and strictly guarantee the product quality.

10. According to the requirements of the aluminum production plan, make a reasonable measurement. When sawing, the feeding speed of the fins shall not be too fast to avoid the end end being injured.

-

Do you know the harm caused by IGBT module overheating?

Do you know the harm caused by IGBT module overheating? IGBT module itself has a certain power, the module itself will generate heat, the overall performance and reliability of IGBT module are affected by temperature. Design rules are often used to compare failure rate figures.According to the design guidelines, one of the design rules shows that the failure rate will double for every 10℃ rise in temperature when the component is operating in an environment above 65℃.So cooling IGBT module is also extremely important work!

IGBT module is high power semiconductor devices, loss power makes the heat more, combined with the IGBT junction temperature should not exceed 125 ℃, should not be long term work at higher temperatures, usually large current through the IGBT module, switching frequency is higher, leads to the wastage of the IGBT device is big also, if the heat is not spread out in time, make the device junction temperature over 125 ℃, IGBT module should not be long-term work under the critical temperature, the damage is bad IGBT heat sink temperature overheat is IGBT damage to affect the operation of the machine work.IGBT overheat may be the cause of bad driving waveform or current is too large or too high switch frequency, also may be due to poor heat dissipation condition, that in the case of cooling bad this plus the corresponding thermal design scheme of the heat sinkis given priority to with transfer and the temperature of the module to allow faster cooling, the purpose of the heat sink is to increase the cooling area, so that the IGBT power device heat is transferred to the air. LORI heat sink products also include IGBT heat sink, we cooperate with many industry users, to provide them with high quality IGBT heat sink, IGBT water cold plate, IGBT heat pipe heat sink and so on.

If IGBT module heat dissipation is not good and the temperature is too hot, it will directly damage or affect the operation of the whole machine. Come to LORI, we have a professional thermal management engineers can provide you with IGBT accurate thermal countermeasures, let your IGBT module away from the danger of overheating, LORI heat sink has always been committed to the development and production of a variety of high power electronic heat sink including IGBT, to provide users with better products, better services.

-

What determines the performance of the zipper fin heat sink ?

Collection mode heat pipe and zipper fins at present there are mainly two kinds, respectively is welding (Solder) and wear a Fin (Fin Penetration), welding process of the interface zipper resistance is low, but the cost is higher, such as aluminum fins and copper heat pipe welding, basic need to electroplating processing of heat pipe, can with aluminum fins welded together, and welding is high also to craft requirement, welding uneven or internal bubble, heat transfer efficiency will be significantly impaired.

Fin piercing is to let heat pipe directly through the Fin by mechanical means. This process is simple, but the technical requirements are no lower than that of welding, because it requires the heat Fin to have close contact with the heat pipe. If Fin piercing fails, not only the zipper efficiency will be greatly reduced, but the zipper Fin may even fall off directly.At the same time, in order to ensure that Fin array does not deform, Fin piercing process is often used in conjunction with Fin buckle technology, that is, the edge of the Fin is bent and adjacent fins are combined in the form of buckle to ensure that the zipper Fin spacing does not change.

In terms of cost, the cost of Fin piercing process is slightly lower than that of welding process, and the theoretical zipper resistance of contact surface is slightly higher than that of welding.To identify which kind of process is adopted for the heat sink, we can see by observing the zipper Fin that the welding process will leave welding holes at the contact position between the zipper Fin and the heat pipe, and the Fin piercing process is that the Fin directly wraps the heat pipe.

It is important to note that the excellent wear Fin process compared with welding process does not have a significant performance difference, this and the area of the cooling fins, thickness and spacing of conclusion, the key still should see the manufacturer’s technology level, but because the welding process has advantage on the durability and stability, so now most high-end heat sink use welding technology, and pay attention to the mainstream of price level product is basic in Fin process.

Conclusion: a good heat sink is not a little protruding, but every point can cooperate with each other

Heat pipe and zipper fins, base, this is the current mainstream type air cooled heat sink mainly made up of three parts, each part of the heat pipe heat sink cooling effectiveness will have an important influence, and three parts are interrelated, part simply increase would not necessarily bring heat sink efficiency of qualitative leap, but is there any part of not ready, for the performance of heat sink is a heavy blow.

Because this is an outstanding wind cool heat sink, often be not to say to have what to outstanding performance in onefold respect, depend on each respect to have better balance however, especially now the light quantification of wind cool heat sink, individuation has incline to mainstream, of this kind of balance maintain can highlight the strength of heat sink manufacturer more.